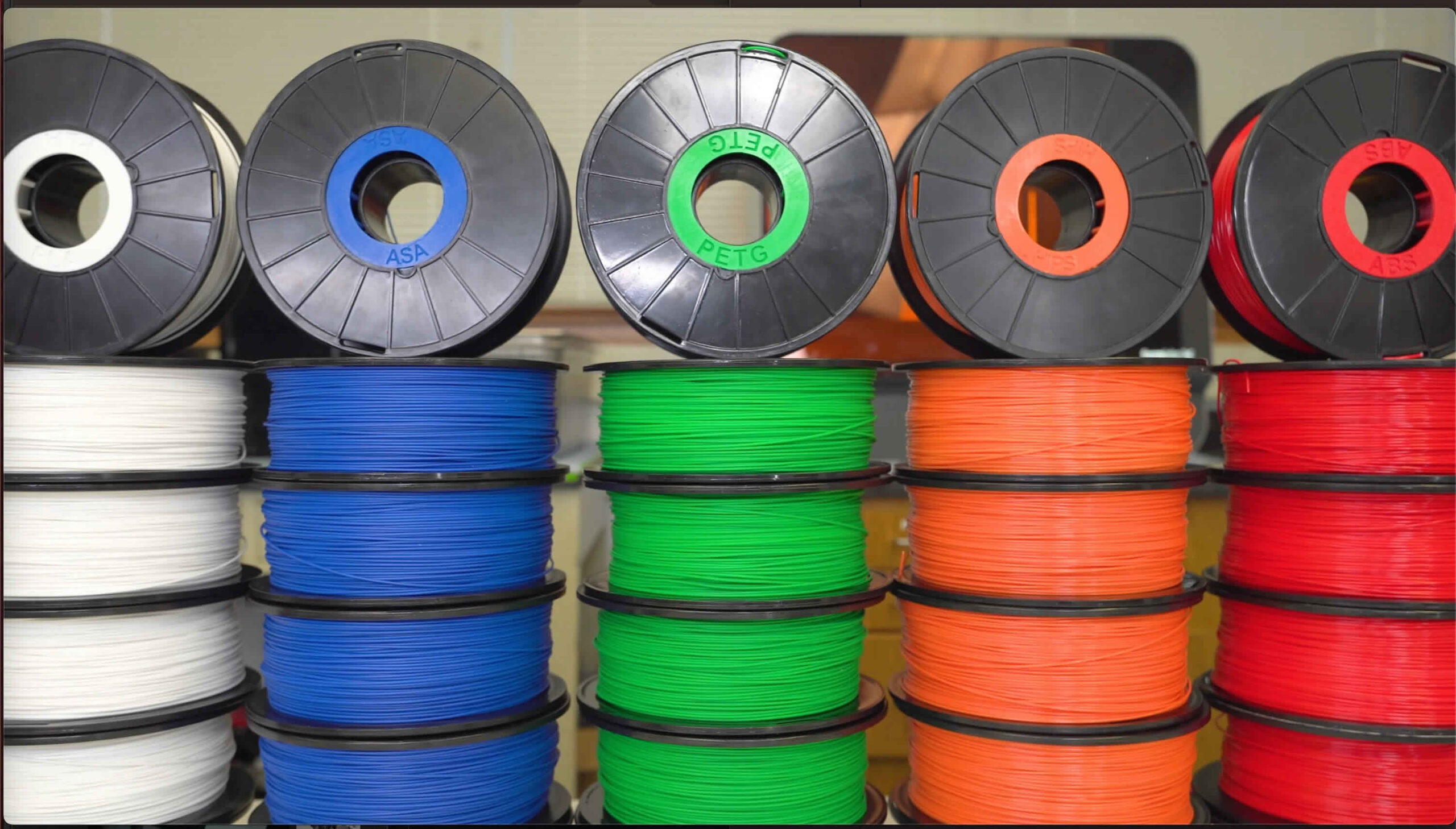

3D printing keeps leveling up every year. Better settings, smarter slicers, advanced hardware, and most importantly, new and improved materials. With so many options on the market, figuring out which filament to choose for each type of project isn’t always straightforward. From hobby creators and engineering students to prototyping labs and small businesses, material choice can make or break a print. Whether you’re upgrading your setup or buying 3D printer filament for the first time, this guide breaks down the best filament types and what makes each one shine.

What Makes a Filament “Best” for Your Project?

Different prints demand different qualities. Think strength, flexibility, finish, color range, heat tolerance, ease of printing, and post-processing needs. The best approach is matching material characteristics to your project’s function, not just picking what’s popular.

Key factors to consider:

- Strength and layer adhesion

- Flexibility or rigidity

- Temperature resistance

- Print difficulty level

- Surface finish and detail capability

Let’s dig into the top filament types and when to use them.

PLA: The Essential All-Rounder

PLA is the starter champion and still one of the most versatile filaments in the ecosystem. It’s affordable, easy to print, odor-free, and great for models, figures, miniatures, and basic prototypes.

Best uses:

- Decorative prints

- Prototypes

- Classroom projects

- Miniatures and art pieces

Upgraded blends like PLA+ or fiber-filled PLA add strength and unique textures, making PLA even better.

PETG: The Strength-Flexibility Balance

If PLA feels too light-duty for you, PETG is the next logical step. It combines durability, impact resistance, and mild flexibility. Plus, it handles outdoor environments better than PLA.

Best uses:

- Mechanical parts

- Outdoor components

- Functional printing

- Cases, brackets, and connectors

It prints hotter than PLA and prefers controlled cooling, but once dialed in, it’s an absolute workhorse.

ABS: Traditional Engineering Material

ABS has been a favorite for years, especially among engineers. Its heat resistance and strength are top-tier, making it ideal for durable prototypes and machine parts. The trade-off? It needs an enclosure and proper ventilation due to fumes and shrinkage.

Best uses:

- Enclosure

- Automotive-style parts

- Durable snap-fit components

ABS is for experienced printers who want reliability under pressure.

TPU & Flexible Filaments: When Elasticity Matters

Need flexibility? TPU brings elasticity, impact absorption, and soft-touch finishes. It’s trickier to print due to its rubber-like nature, but perfect for functional parts that bend instead of break.

Best uses:

- Grips and phone cases

- Wearables

- Custom gaskets and hinges

Nylon: Industrial Strength

Nylon is incredibly durable, abrasion-resistant, and strong. It’s a favorite in industrial prototyping and manufacturing settings. It requires specific drying and storage methods because it loves absorbing moisture, but the results are professional-grade.

Best uses:

- High-stress mechanical parts

- Gears and bushings

- End-use components

Specialty Filaments: Creative and Technical Upgrades

If you’re ready to explore, specialty materials take printing to new zones:

- Carbon-fiber blends for lightweight toughness

- Wood-filled PLA for organic textures

- Silk PLA for shiny artistic models

- Metal-infused filaments for weight and metallic feel

These offer unique aesthetics and performance upgrades but often ask for hardened nozzles and tuned settings.